STL Files: The Backbone of 3D Printing

STL files, short for Stereolithography files, are the cornerstone of 3D printing and digital modeling. Developed in the late 1980s by 3D Systems, these files have become a universal standard in the realm of additive manufacturing. Let’s dive into what STL files are, their structure, and their pivotal role in the 3D printing ecosystem.

What is an STL File?

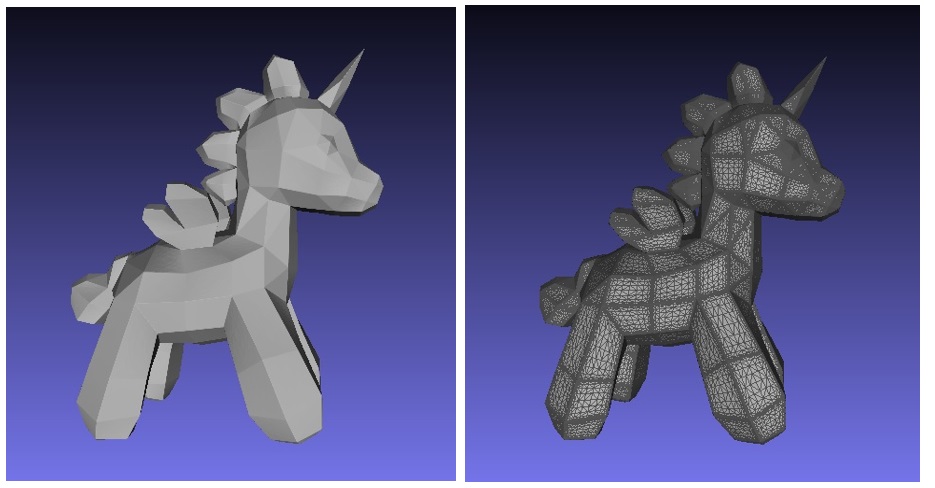

An STL file is a type of file format native to the stereolithography CAD software created by 3D Systems. These files are used to store information about 3D models, specifically focusing on the surface geometry of the model. STL files do not capture color, texture, or other common CAD model attributes but instead represent the 3D object’s surface as a mesh of triangles.

Structure of STL Files

STL files come in two formats: ASCII and binary. While both serve the same purpose, they differ in how the data is stored.

- ASCII STL Files: These files are human-readable, consisting of plain text that describes the vertices of each triangle. They begin with a header (“solid name”) and end with a footer (“endsolid name”), containing a list of facets in between.

Example:

sqlsolid cube

facet normal 0 0 0

outer loop

vertex 0 0 0

vertex 1 0 0

vertex 0 1 0

endloop

endfacet

endsolid cube

- Binary STL Files: These files are more compact and efficient in terms of storage and processing speed. A binary STL file starts with an 80-byte header followed by a 4-byte integer indicating the number of triangles. Each triangle is then described using 12 bytes for the three vertex coordinates, followed by 12 bytes for the normal vector, and 2 bytes for an attribute byte count.

Advantages of STL Files

- Simplicity: The straightforward structure of STL files makes them easy to generate and interpret by 3D printers and CAD software.

- Universality: STL is widely accepted across various 3D modeling and printing platforms, ensuring compatibility.

- Efficiency: The binary format is particularly efficient in terms of file size, which is crucial for handling complex models.

Limitations of STL Files

Despite their widespread use, STL files have certain limitations:

- Lack of Detail: STL files do not store color, texture, or material information, which limits their use in applications requiring detailed representation.

- Approximation Errors: The triangulated representation of surfaces can lead to approximation errors, especially for curved surfaces.

- File Size: While binary STL files are compact, highly detailed models can still result in large file sizes, posing challenges for storage and processing.

Applications of STL Files

STL files are predominantly used in:

- 3D Printing: They serve as the primary file format for transferring 3D models to printers, ensuring accurate replication of designs.

- Prototyping: Engineers and designers use STL files to create prototypes, allowing for physical evaluation and testing of designs before mass production.

- Medical Modeling: STL files are employed in the medical field to create accurate models of anatomical structures for surgical planning and educational purposes.

Differences Between ASCII and Binary STL Formats

ASCII STL Format

The ASCII STL format represents 3D models in a human-readable text format. Each facet of the 3D object is described with a series of plain text lines. An ASCII STL file starts with a header line, followed by multiple facet descriptions, and ends with an “endsolid” keyword.

Example of ASCII STL Format:

solid object_name

facet normal ni nj nk

outer loop

vertex v1x v1y v1z

vertex v2x v2y v2z

vertex v3x v3y v3z

endloop

endfacet

endsolid object_name

- Human-Readable: ASCII STL files can be opened and read with any text editor, making them easy to debug and modify manually.

- Larger File Size: Because it uses plain text to describe each facet, ASCII STL files tend to be larger compared to their binary counterparts.

- Slower Processing: Due to their larger size and text-based format, ASCII STL files take longer to process in CAD and 3D printing software.

Binary STL Format

The Binary STL format represents 3D models in a more compact, non-human-readable format. It begins with an 80-character header, followed by a 4-byte integer indicating the number of facets. Each facet is described using a fixed-length 50-byte structure.

Structure of Binary STL Format:

- 80-byte Header: Contains no standard information and is often left blank.

- 4-byte Integer: Indicates the number of triangles (facets) in the file.

- 50-byte Facet Description:

- 12 bytes for the normal vector (3 floats)

- 36 bytes for the three vertices (9 floats)

- 2 bytes for the attribute byte count (often set to zero)

Example of Binary STL Structure:

| Header | Number of Facets | Facet 1 | Facet 2 | … |

|---|---|---|---|---|

| 80 bytes | 4 bytes | 50 bytes (Facet Data) | 50 bytes (Facet Data) | … |

- Compact Size: Binary STL files are more compact than ASCII files, making them faster to read and write.

- Not Human-Readable: Binary STL files cannot be easily read or edited with a text editor.

- Faster Processing: Due to their smaller size and binary format, they are quicker to process by 3D software.

Special Rules for the STL File Format

Regardless of whether the STL file is in ASCII or Binary format, certain rules must be followed to ensure the file is valid and can be interpreted correctly by 3D printing and CAD software.

- Facet Orientation:

- Each facet must be defined by a normal vector pointing outwards, followed by three vertices.

- The vertices must be ordered consistently (e.g., in a counter-clockwise direction when viewed from the outside).

- Facet Normal Calculation:

- The normal vector should be perpendicular to the triangle surface. While this can be calculated from the vertex coordinates, it must be explicitly defined in the file.

- Units:

- STL files do not include any units information. The software interpreting the STL file must assume a unit (e.g., millimeters, inches).

- Manifold Geometry:

- The 3D object represented by the STL file should be a “watertight” solid, meaning it has no holes, overlapping facets, or unconnected edges.

- Consistency:

- All vertices and normal vectors must be consistently defined to ensure that the 3D model can be accurately rendered and printed.

How is an STL File 3D Printed?

STL (Stereolithography) files are the standard file format used for 3D printing. They represent 3D models as a mesh of triangles, describing the surface geometry of the object without any color, texture, or other attributes.

Steps to 3D Print an STL File:

- Design or Obtain the STL File: Create a 3D model using CAD software or download a pre-designed STL file from online repositories.

- Prepare the STL File: Use slicing software to convert the STL file into G-code, which contains instructions for the 3D printer. The slicing software slices the model into horizontal layers and determines the optimal path for the printer head.

- Set Up the 3D Printer: Configure the 3D printer settings, including temperature, print speed, layer height, and material type.

- Print the Object: Load the G-code file into the 3D printer and start the printing process. The printer will follow the G-code instructions to build the object layer by layer.

- Post-Processing: After printing, some models may require cleaning, removal of supports, and additional finishing such as sanding or painting.

Is Every STL File 3D Printable?

Not all STL files are 3D printable. Several factors determine the printability of an STL file:

- Manifold Geometry: The model must be watertight, meaning there are no gaps, holes, or non-manifold edges in the mesh.

- Size and Scale: The model must fit within the build volume of the 3D printer.

- Orientation and Support: Complex geometries may require support structures to print correctly. The orientation of the model on the print bed can affect the need for supports and the quality of the print.

- Detail Resolution: The level of detail in the STL file should match the capabilities of the 3D printer. Very fine details might not print well on a printer with a larger nozzle size.

- Material Compatibility: The STL file design should be suitable for the material being used. For example, certain designs may be better suited for flexible filaments, while others are more appropriate for rigid plastics.

How to Optimize STL Files

Optimizing STL files ensures better print quality and efficiency. Here are some steps to optimize STL files:

- Reduce Polygon Count: Simplify the mesh to reduce the number of triangles without losing significant detail. This reduces the file size and processing time.

- Ensure Manifold Geometry: Use software tools to repair and ensure the model is watertight with no gaps or holes.

- Optimize Wall Thickness: Ensure that walls are thick enough to print properly but not excessively thick, which can waste material and increase print time.

- Improve Mesh Quality: Remove any non-manifold edges, overlapping triangles, and other mesh errors.

- Add Support Structures: Use slicing software to automatically or manually add support structures for overhangs and complex geometries.

- Orient the Model Properly: Position the model on the print bed to minimize supports, reduce print time, and improve surface quality.

Color Printing with STL Files

STL files do not inherently support color information. However, there are ways to achieve color printing:

- Multi-Material Printing: Use a multi-material 3D printer that can print with different filaments. This requires splitting the STL file into different parts, each corresponding to a different color or material.

- Painting: Print the model in a single color and then paint it post-printing.

- Texture Mapping: Convert the STL file to a format that supports textures, such as OBJ or VRML, and use a color 3D printer that can handle these formats.

- Color Filament Changes: Manually change the filament color during the print process to achieve different colors in a single print.

STL File Resources

There are numerous online repositories where you can find STL files for 3D printing:

- Thingiverse: A popular platform with thousands of free STL files uploaded by the community.

- MyMiniFactory: A curated collection of STL files, ensuring high-quality and printability.

- Cults: A marketplace for STL files where you can find both free and paid models.

- GrabCAD: A community-driven platform with a large library of CAD files, including STL files for 3D printing.

- CGTrader: A marketplace offering a wide range of 3D models, including STL files for printing.

By understanding the intricacies of STL files and the 3D printing process, you can ensure successful prints and explore a wide range of creative possibilities.

Is STL Repair Software and Services: An Overview

In the realm of 3D printing and computer-aided design (CAD), STL (Stereolithography) files play a pivotal role. These files, used for 3D models, often require precise and error-free data for successful printing. This is where STL repair software and services come into play, ensuring the integrity and functionality of 3D models. Let’s delve into the significance, functionality, and benefits of STL repair solutions.

Importance of STL Repair

- Print Quality: High-quality 3D prints require flawless STL files. Errors in these files can lead to print failures, defects, and inaccuracies. STL repair ensures that the models are correctly interpreted by 3D printers, resulting in better print quality.

- Time and Cost Efficiency: Repairing STL files before printing saves time and resources. Failed prints can be costly and time-consuming, making preemptive repairs a cost-effective strategy.

- Complex Models: For intricate designs and complex models, the likelihood of errors increases. STL repair software is particularly useful for handling such complexities, ensuring the models are accurately rendered.

STL Repair Software

- Netfabb: Developed by Autodesk, Netfabb is a comprehensive tool for STL file repair and optimization. It offers a range of features including automated repair, mesh editing, and model optimization.

- Meshmixer: Also from Autodesk, Meshmixer is a versatile tool for working with 3D meshes. It includes robust STL repair capabilities, making it a favorite among 3D printing enthusiasts.

- Magics: Materialise’s Magics is a powerful software suite for additive manufacturing. It offers extensive tools for STL repair, including automated fixing and advanced mesh manipulation.

STL Repair Services

For those who prefer outsourcing the repair process, several companies offer STL repair services. These services typically involve experts who manually inspect and repair STL files, ensuring high-quality results. This can be particularly beneficial for businesses dealing with complex or high-volume 3D printing projects.

Conclusion

STL repair software and services are essential components of the 3D printing ecosystem. By ensuring the integrity and functionality of STL files, they play a crucial role in achieving high-quality 3D prints. Whether through automated software solutions or professional services, STL repair is a key step in the journey from digital model to physical object, enhancing the efficiency and success of 3D printing projects.